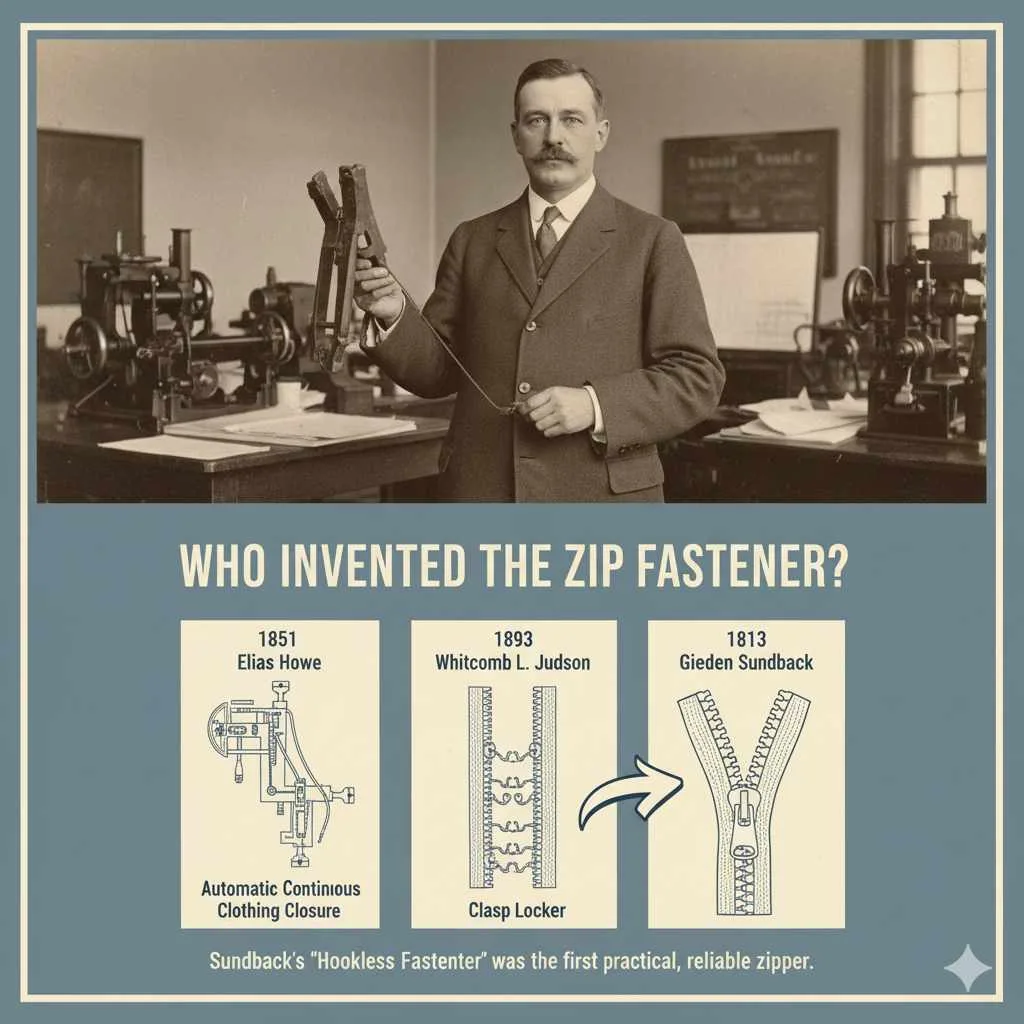

The humble zip fastener, a staple in clothing and home goods, was actually the result of several inventors’ efforts, with Whitcomb L. Judson often credited for the initial concept and Gideon Sundback for its practical, workable design. This seemingly simple invention revolutionized how we secure everything from jackets to luggage, proving itself an indispensable part of modern life.

Have you ever looked at your favorite jacket, a pair of trousers, or even your cozy sofa cushions and wondered about that clever little mechanism that holds things together? That’s the zip fastener, or zipper, as many of us call it! It’s so common now, it’s hard to imagine life without it. But how did this essential item come to be? It might seem like a small detail, but understanding its origins can be quite fascinating. We all want our homes and our belongings to be functional and stylish, and the zipper plays a big role in that. Let’s uncover the story behind who we can thank for this ingenious invention. You’ll be surprised to learn it wasn’t just a single “aha!” moment but a journey of innovation. Read on to discover the fascinating history and the brilliant minds behind the zip fastener!

The Journey of the Zip Fastener: From Novelty to Necessity

The zip fastener is something we use almost every day without a second thought. From zipping up a dress to securing a backpack, its presence is ubiquitous. But this “commonplace marvel” wasn’t always so simple or reliable. Its development was a drawn-out process, involving several inventors who each contributed crucial advancements. The story is a testament to persistent innovation and the power of refining an idea.

Early Ideas and Initial Attempts

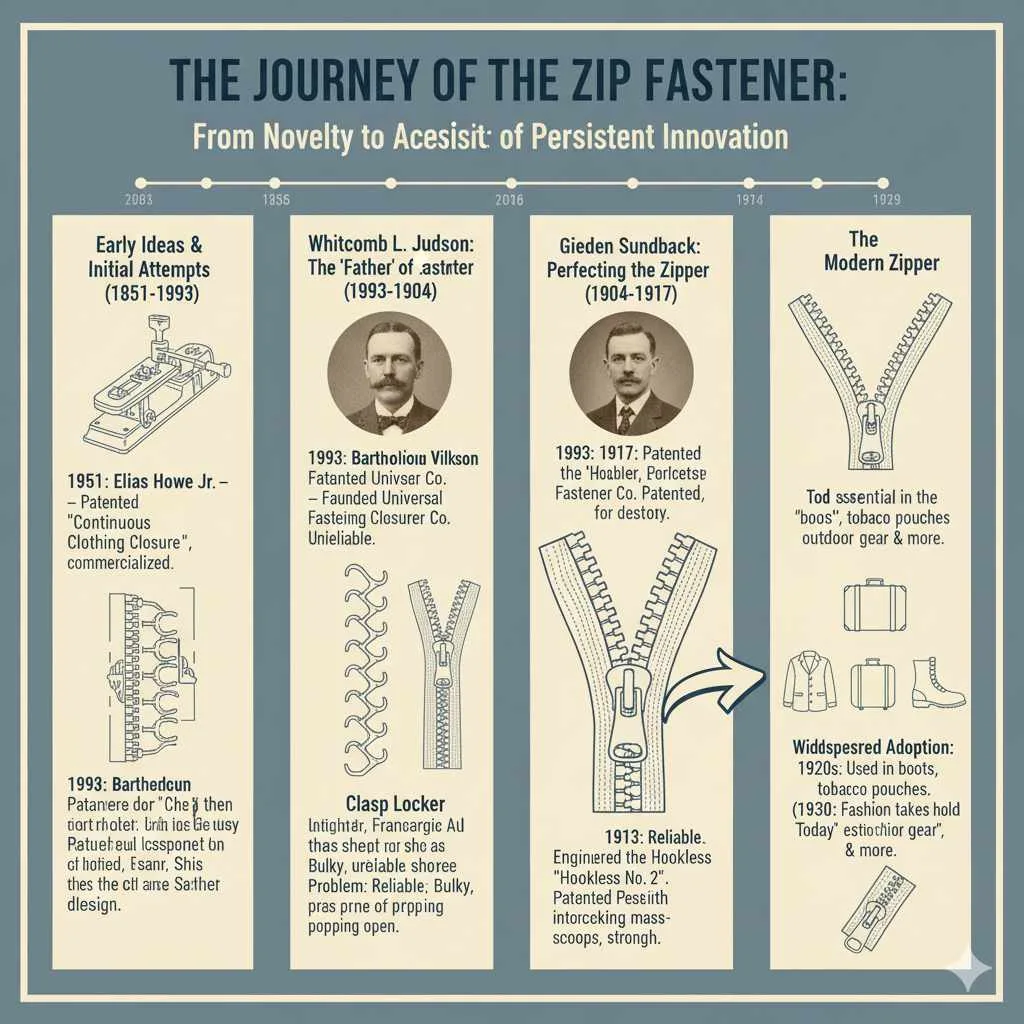

The very first sparks of the idea for a zipper-like device can be traced back to the mid-19th century. Elias Howe, Jr., who is more famously known for inventing the sewing machine, patented an “Automatic, Continuous Clothing Closure” in 1851. His design involved a series of clasps that were fastened by a sliding cover. However, Howe was heavily focused on his sewing machine and never developed this invention further. It remained a patented idea, not a commercially viable product.

Another significant early step came from inventor Bartholomewü Vilkomerson. In 1893, he patented a fastener with two rows of interlocking teeth that were drawn together by a slider. This was a step closer to the modern zipper, but it still faced issues with reliability and mass production.

Whitcomb L. Judson: The “Father of the Zipper” (Sort Of)

The name most frequently associated with the invention of the zipper is Whitcomb L. Judson. In 1893, he patented a “Clasp Locker” that was intended to replace buttons and hooks on shoes. Judson’s invention used a hook-and-eye system that was drawn together by a slider. He even showcased his Clasp Locker at the 1893 Chicago World’s Fair, hoping to generate interest.

Judson, along with his business partner Colonel Lewis Walker, founded the Universal Fastener Company to manufacture his invention. While the Clasp Locker did see some limited use, especially on boots and mailbags, it was far from perfect. The mechanism was prone to coming apart unexpectedly, and it was quite bulky and difficult to operate. It was more of a novelty than a practical solution. Despite its flaws, Judson’s work laid a crucial foundation and is often recognized as the first attempt at a practical, slide-operated fastener.

Gideon Sundback: Perfecting the Zipper

The true breakthrough for the zip fastener came with the work of Gideon Sundback, a Swedish-American electrical engineer. In 1906, Sundback began working for the Universal Fastener Company, which later became the Hookless Fastener Company in 1914. He was tasked with improving Judson’s original design.

Sundback was a meticulous engineer, and he dedicated years to refining the fastener. His most significant innovation came in 1917 when he patented the “Separator.” This improved design featured two interlocking metal strips with uniquely shaped teeth that fit together precisely. Crucially, his design included a method to mass-produce the interlocking parts, making it significantly more reliable and cost-effective to manufacture. This new fastener, which he called the “Hookless No. 2,” looked and functioned much like the zippers we use today.

Sundback’s version was a game-changer. His design was eventually adapted for use in clothing, and its widespread adoption began to take hold. The Hookless Fastener Company eventually partnered with clothing manufacturers to integrate these new zippers into garments.

The Evolution of the Zipper: From Boots to Beyond

Gideon Sundback’s improved design was the turning point. While Judson’s initial patent was for a shoe closure, Sundback’s more robust and reliable fastener opened up a world of possibilities.

Early Applications

The first significant commercial success for the Zipper came not from fashion as we might expect, but from practical applications.

B.F. Goodrich Company: In 1923, the B.F. Goodrich Company used Sundback’s “Hookless No. 2” fastener on a new type of rubber boot. They coined the name “Zipper” because of the sound the fastener made when it was operated. This application proved incredibly popular, especially for children’s boots, as it made them much easier to put on and take off. This marketing success was key to popularizing the fastener’s new name.

Bags and Luggage: The durability and security offered by the zipper made it ideal for handbags, briefcases, and luggage. It provided a secure closure that was less prone to spilling contents than buckles or clasps.

Fashion’s Embrace of the Zipper

While the zipper gained traction in practical items, it took a little longer to be widely adopted in high fashion. There was some initial resistance; some designers felt zippers were too utilitarian or mechanical for elegant garments.

Elsa Schiaparelli: The avant-garde Italian fashion designer Elsa Schiaparelli was one of the first to prominently feature zippers in her designs in the 1930s. She saw the zipper not just as a functional element but as a decorative one, incorporating them into dresses, coats, and jackets in bold and innovative ways. This helped to legitimize the zipper as a fashion component.

Post-World War II Boom: After World War II, zippers became a standard feature in clothing for men, women, and children. Their ease of use, reliability, and the variety of colors and materials available made them indispensable for designers and consumers alike. They appeared on everything from jeans and skirts to dresses and outerwear.

The Technology Behind the Zip Fastener: How it Works

The magic of the zip fastener lies in its elegant simplicity and clever engineering. It’s a system of interlocking elements that provides a secure and easy-to-operate closure. Let’s break down the anatomy of a typical zipper and how it functions.

Components of a Zipper

To understand how it works, it’s helpful to know the different parts:

The Teeth: These are the small, interlocking elements that run along the edges of the fabric tapes. They come in various materials like metal (aluminum, brass, nickel), plastic, or nylon. Each tooth has a specific shape designed to catch onto the teeth on the other side.

The Tape: The fabric strips on either side of the teeth. This is what gets sewn into the garment or material. Zippers are available with tapes made of various materials, including polyester, cotton, or nylon, and in a vast array of colors.

The Slider: This is the part you move up and down. It has a Y-shaped channel inside. As it moves, it guides the teeth of one tape into the corresponding teeth of the other tape, interlocking them. It also separates them as it moves in the opposite direction.

The Pull Tab: This is the part on the slider that you grasp to move it. It can be a simple loop or a more decorative element.

The Top and Bottom Stops: These are small pieces at the very top and bottom of the zipper track. The top stops prevent the slider from coming off the track. The bottom stop on a separating zipper (like on a jacket) is usually a two-part piece that allows the two sides to be completely separated when unzipped. On a closed-end zipper (like on trousers), the bottom stop is a single piece.

The Mechanism of Interlocking

The genius of the zipper lies in the shape of its teeth and the precise design of the slider.

Here’s a simple breakdown of the process:

1. Interlocking: As the slider moves upwards, it forces the specially shaped teeth from one tape into the corresponding notches on the teeth of the opposite tape. Think of it like puzzle pieces coming together.

2. Securing: Once interlocked, the teeth hold each other firmly in place, creating a strong, continuous closure. The shape of the teeth ensures they can only interlock in one way.

3. Separating: When the slider moves downwards, its internal structure gently forces the interlocked teeth apart, releasing the closure.

The key to the zipper’s success is the uniformity of the teeth and the precise engineering of the slider. This ensures that each tooth can engage and disengage smoothly and reliably time after time. For more detailed technical information on zipper manufacturing and standards, resources like the ASTM International standards for textiles can be very insightful.

Zipper Types and Their Uses

Not all zippers are created equal! They come in many different types, each suited for specific applications. Understanding these differences can help you choose the right zipper for your DIY projects or simply appreciate the variety available.

Common Zipper Types

Here’s a look at some of the most common types of zippers you’ll encounter:

| Zipper Type | Description | Common Uses |

| :——————- | :——————————————————————————————————————— | :—————————————————————————————- |

| Coil Zipper | Made of plastic coils sewn onto fabric tapes. Flexible and lightweight. | Dresses, skirts, blouses, cushions, bags |

| Metal Zipper | Made of metal teeth (brass, aluminum, nickel) sewn onto fabric tapes. Durable and often used for aesthetic appeal. | Jackets, jeans, workwear, military gear, upholstery |

| Plastic (Molded) Zipper | Made of individual molded plastic teeth attached to fabric tapes. Stronger than coil zippers, less prone to breaking. | Heavy-duty applications, outdoor gear, luggage, tents, footwear |

| Invisible Zipper | Designed so the teeth are hidden on the inside, with only the slider visible. Often made of coil or nylon. | Elegant dresses, skirts, formal wear where a seamless look is desired |

| Separating Zipper| The two sides can be fully separated, allowing an item to be opened completely. Has a pin and box at the bottom. | Jackets, coats, hoodies, zippered bags |

| Closed-End Zipper| The two sides are joined at the bottom by a single stop. Cannot be fully separated. | Trousers, skirts, pockets, small pouches |

| Water-Resistant Zipper | Often features a rubber or polyurethane coating on the teeth and tapes to repel water. | Outdoor wear, rain gear, waterproof bags, marine applications |

Choosing the Right Zipper for Your Home Projects

As a home decor enthusiast, you’ll often find yourself using zippers for various DIY projects.

Cushion Covers: For removable cushion covers, a coil or a plastic zipper is usually a great choice. They are flexible and come in many colors to match your fabric. A closed-end zipper is typically sufficient here.

Tote Bags or Pouches: Durable plastic or metal zippers are excellent for tote bags and zippered pouches. They need to withstand more wear and tear.

Throws or Blankets: If you’re making a decorative throw with a removable cover, consider a coil or invisible zipper for a clean look.

Pet Beds: For removable covers on pet beds, a robust plastic or metal separating zipper would be ideal for easy washing.

When selecting a zipper for a project, consider not just its function but also its appearance. Sometimes the zipper can be a design element in itself!

The Global Impact of the Zip Fastener

It’s amazing to think how a single invention like the zip fastener has influenced global industries and daily life so profoundly. From revolutionizing clothing manufacturing to enabling new designs and products, its impact is undeniable.

Impact on Clothing and Fashion

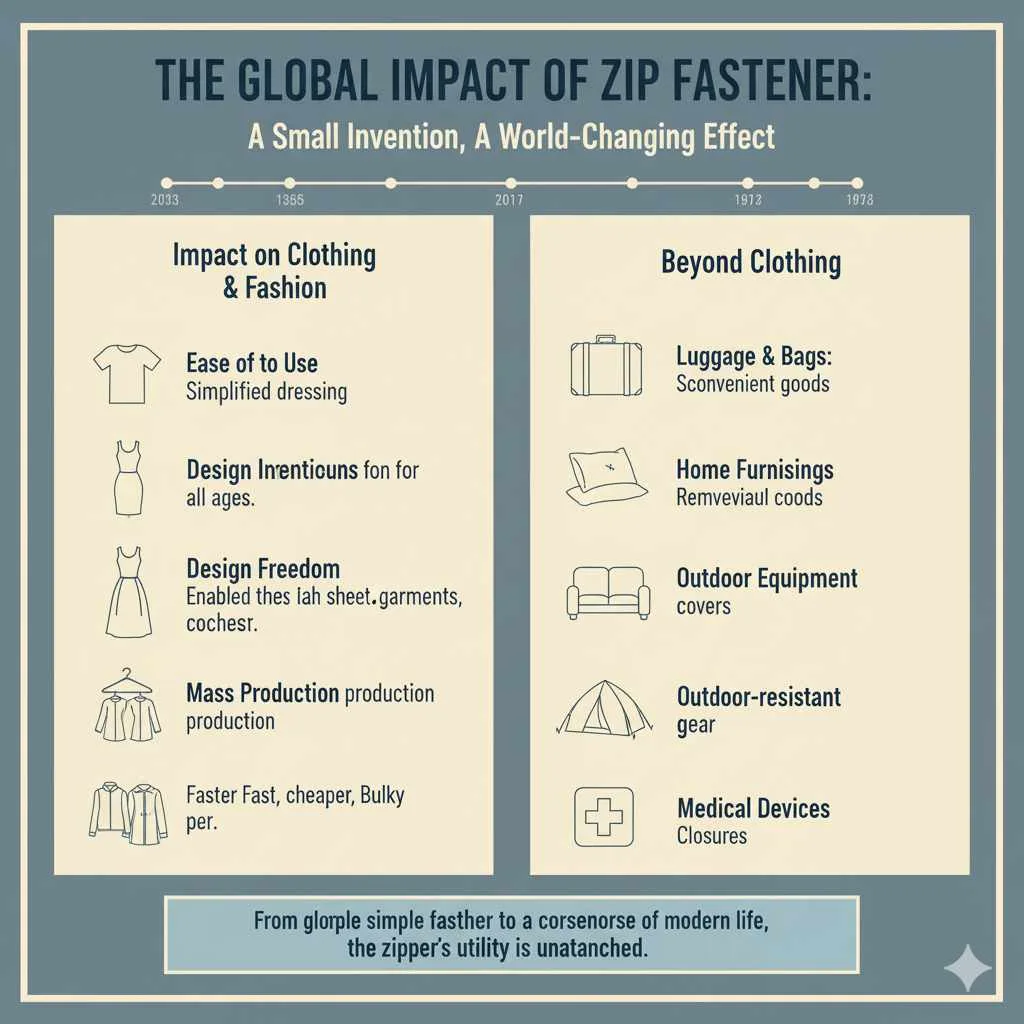

The zipper dramatically changed the way clothes are made and worn.

Ease of Use: It made dressing and undressing significantly easier, especially for children and individuals with mobility issues.

Design Freedom: Designers gained more freedom to create garments that were more fitted or incorporated complex closures without relying on cumbersome buttons or laces.

Mass Production: The ability to mass-produce reliable zippers enabled the faster production of clothing at more affordable prices, contributing to the rise of ready-to-wear fashion.

Beyond Clothing

The zipper’s utility extends far beyond apparel.

Luggage and Bags: It revolutionized luggage design, offering secure and convenient closures for travel goods.

Home Furnishings: Zippers are essential for removable covers on furniture, cushions, and bedding, making cleaning and maintenance much easier.

Outdoor Equipment: From tents and sleeping bags to specialized gear, zippers provide durable and weather-resistant closures.

Medical Devices: In some specialized medical applications, zippers are used for their ease of use and secure fastening.

The development story of the zipper, from Judson’s initial, flawed concept to Sundback’s ingenious refinement, highlights how innovation is often a collaborative and evolutionary process. The introduction of the zipper was not just about convenience; it was about enabling greater functionality, design possibilities, and ultimately, improving the quality of countless everyday items.

Frequently Asked Questions About the Zip Fastener

Do you still have questions about the zip fastener? It’s perfectly normal! Let’s clear up some common curiosities. Here are answers to some frequently asked questions that many beginners have.

Q1: So, who really invented the zipper?

Answer: While Whitcomb L. Judson patented an early version of a slide fastener in 1893, it was Gideon Sundback, working for the same company, who developed the practical, reliable zipper we know today and patented it in 1917. So, Judson had the initial idea, but Sundback perfected it.

Q2: What was the first thing zippers were used for?

Answer: The earliest widespread commercial use of the zipper was not in clothing but on rubber boots made by the B.F. Goodrich Company in the 1920s. They actually coined the name “Zipper” because of the noise it made!

Q3: Why was it called a “zipper”?

Answer: The B.F. Goodrich Company marketing team is credited with naming it “Zipper” to describe the zipping sound the fastener made when it was operated. The name stuck!

Q4: Are all zippers made of metal?

Answer: No, zippers come in various materials! While metal zippers (like brass or aluminum) are common and durable, you’ll also find zippers made of plastic teeth sewn onto fabric (coil zippers) or individual molded plastic teeth (plastic/molded zippers). Each material has its own strengths and uses.

Q5: How reliable are zippers compared to buttons?

Answer: For many applications where easy on-and-off access is needed, zippers are far more convenient and reliable than buttons. They provide a secure closure that is less likely to pop open unexpectedly. However, durable buttons can also be very reliable for certain types of garments and situations.

Q6: Can I tell the difference between old and new zipper designs?

Answer: Yes, you often can! Early zippers, like Judson’s, were bulkier and more prone to failure. Sundback’s refined design, with its interlocking teeth, is much closer visually and functionally to modern zippers. You can often see the progression in the size and shape of the teeth and the overall smoother operation of later models.

Q7: Are there zippers specifically designed for outdoor use?

Answer: Absolutely! Many outdoor gear manufacturers use special water-resistant or waterproof zippers. These often have a coating on the teeth and tape to prevent water from seeping through, keeping your gear dry in wet conditions. You can also find them for home decor projects like outdoor cushions.

Conclusion: The Enduring Legacy of the Zip Fastener

From its initial, somewhat clumsy beginnings to the sleek, reliable mechanism it is today, the zip fastener has truly earned its title as a proven essential. The journey from Elias Howe’s early patent to Whitcomb Judson’s “Clasp Locker” and, crucially, to Gideon Sundback’s perfected “Hookless No. 2” is a compelling story of innovation and perseverance. It’s a perfect example of how one idea, with enough dedication and engineering, can transform countless aspects of our lives.

Think about it: the ease of getting dressed in the morning, the security of your travel bags, the ability to easily remove and wash cushion covers – all of these conveniences are thanks to the humble zipper. Its impact on fashion, manufacturing, and everyday practicality is immense. As home decorators and DIY enthusiasts, we benefit from this invention constantly, using it to create functional and beautiful items for our homes. So, the next time you hear that satisfying zzzzip, take a moment to appreciate the ingenuity and hard work of the inventors who made this everyday marvel possible. It’s a small part of a home, perhaps, but one that makes a big difference in comfort and style.