Anodized cookware refers to aluminum pans that have undergone an electrochemical process to create a hard, non-reactive, and durable surface. This process makes the cookware stronger than stainless steel, scratch-resistant, and prevents the aluminum from leaching into your food, making it a safe and long-lasting choice for your kitchen.

Have you ever been shopping for new pots and pans and seen the term “hard-anodized”? It sounds fancy and technical, leaving many home cooks wondering what it actually means. You might ask yourself if it’s just another marketing buzzword or if it genuinely makes a difference in your daily cooking. It can be frustrating to invest in new cookware without knowing if you’re making the right choice.

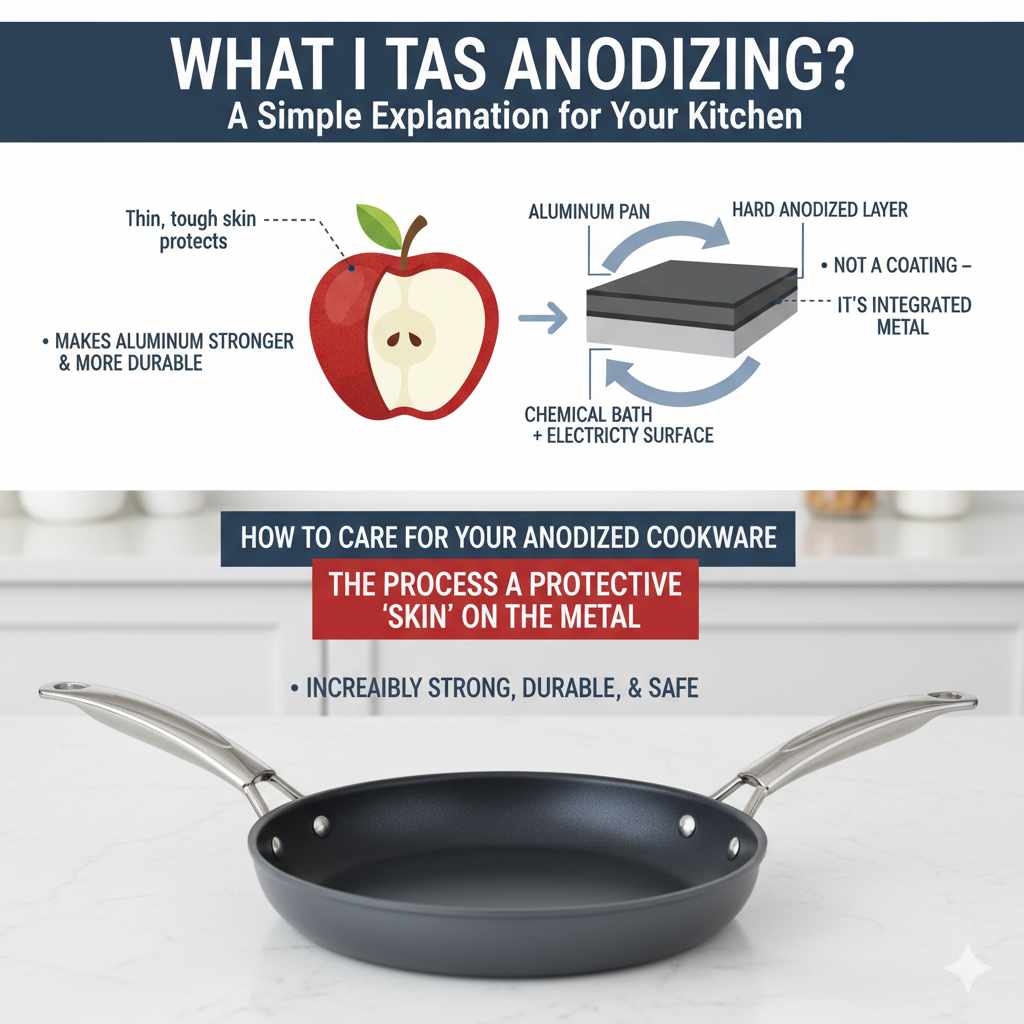

What Is Anodizing? A Simple Explanation for Your Kitchen

At its core, anodizing is a science-backed process that makes aluminum stronger and more durable. While it sounds complex, the idea is quite simple. Think of an apple. An apple has a thin, tough skin that protects the soft fruit inside. The anodizing process creates a similar protective “skin” on the surface of an aluminum pan.

This isn’t a coating like paint or a nonstick layer that can chip or peel off. Instead, the process uses electricity and a chemical bath to change the actual surface of the aluminum. It builds a thick, hard layer of aluminum oxide that is fully integrated with the metal underneath. This new surface is much tougher than the original aluminum.

So, when you see “anodized cookware,” it simply means you’re looking at an aluminum pan that has been fortified to be incredibly strong, durable, and safe for cooking all kinds of food.

How Is Anodized Cookware Made? The Step-by-Step Process

Creating an anodized pan is a fascinating journey from soft metal to a kitchen workhorse. While it happens on an industrial scale, understanding the steps helps you appreciate the quality of the final product. Here’s a simplified look at how it’s done:

- Cleaning the Pan: First, a standard aluminum pan is thoroughly cleaned and rinsed. This removes all oils, dirt, and impurities from the surface to ensure the anodizing process works perfectly. The pan must be completely spotless.

- The Acid Bath: Next, the clean aluminum pan is submerged in a chemical bath, usually made of a solution like sulfuric acid. This might sound intense, but it’s a controlled and essential step. This bath is called an electrolyte.

- Introducing an Electric Current: An electric current is passed through the acid bath. The aluminum pan acts as the positive electrode (the “anode,” which is where the name “anodized” comes from), and a negative electrode is also placed in the bath.

- Building the Protective Layer: The electricity causes a chemical reaction. Oxygen ions are released from the bath and bond with the surface of the aluminum pan. This builds a structured, super-hard layer of aluminum oxide. The longer the pan stays in the bath with the current running, the thicker and harder this layer becomes.

- Sealing the Surface: Finally, the pan is removed and the process is completed by sealing the surface. This is often done by boiling the pan in deionized water. This final step closes off the microscopic pores in the new oxide layer, making it smooth, non-porous, and ready for use.

This entire process transforms a basic aluminum pan into a high-performance piece of cookware that resists scratches, stains, and corrosion.

Hard-Anodized vs Regular Anodized: What’s the Difference?

You will most often see the term “hard-anodized” when shopping for cookware. While both regular and hard anodizing use the same basic process, the difference lies in the intensity and the result. Hard anodizing takes the process a step further to create an even tougher product.

Think of it like baking a cake. You can bake a cake at a normal temperature for a standard amount of time, and it will be good. But if you adjust the temperature and time perfectly, you can get a cake with an amazing crust and a perfect inside. Hard anodizing is like that perfected recipe.

During hard anodizing, a much higher voltage electrical current is used, and the acid bath is chilled to near-freezing temperatures. This combination creates a layer of aluminum oxide that is significantly thicker, denser, and harder than what regular anodizing produces. This is why hard-anodized cookware is so prized for its extreme durability.

Comparison: Hard-Anodized vs. Regular Anodized

Here is a simple table to show you the key differences at a glance:

| Feature | Regular Anodized Aluminum | Hard-Anodized Aluminum |

|---|---|---|

| Durability | More durable than plain aluminum. | Extremely durable. Up to twice as hard as stainless steel. |

| Surface Thickness | A relatively thin protective layer. | A much thicker and denser protective layer. |

| Scratch Resistance | Good resistance to scratches. | Excellent resistance to scratches and abrasions. |

| Color | Usually a light to medium gray. | Typically a darker, charcoal gray or black color. |

| Cost | Generally less expensive. | More expensive due to the more intensive process. |

| Common Use | Found in some bakeware and budget-friendly cookware. | The standard for high-quality, durable cookware. |

For most kitchens, hard-anodized cookware is the recommended choice because its superior strength means it will last longer and stand up better to the demands of everyday cooking.

The Top Benefits of Using Anodized Cookware

So, why should you consider adding anodized cookware to your kitchen? The benefits go far beyond just being strong. Here’s what makes it a favorite among both home cooks and professional chefs.

- Incredible Durability: As we’ve discussed, hard-anodized cookware is exceptionally tough. It resists scratches, chips, and dings far better than traditional nonstick or even stainless steel pans. This means your investment will last for years.

- Excellent Heat Conduction: The core of anodized cookware is aluminum, which is one of the best materials for conducting heat quickly and evenly. This eliminates “hot spots” in your pan, so your food cooks uniformly without burning in one area and being undercooked in another.

- Non-Reactive Surface: The anodized layer acts as a barrier between your food and the aluminum. This is important because plain aluminum can react with acidic foods like tomatoes, wine, or lemons, which can alter the taste of your dish and discolor the pan. Anodized cookware is non-reactive, so your food’s flavor stays pure.

- Lighter Weight: Compared to other durable materials like cast iron, hard-anodized aluminum is much lighter. This makes the pans easier to handle, lift, and maneuver around the kitchen, which is a big plus for everyday use.

- Often Comes with a Nonstick Coating: Most hard-anodized pans also include a high-quality, PFOA-free nonstick coating on the interior cooking surface. This gives you the best of both worlds: the extreme durability of the pan’s body and the easy food release and cleanup of a nonstick surface.

- Easy to Clean: Thanks to the smooth, sealed surface (and often a nonstick coating), anodized cookware is typically very easy to clean. Food doesn’t stick as much, and a simple wash with soap and water is usually all it takes.

Are There Any Downsides to Anodized Cookware?

While anodized cookware has many advantages, it’s helpful to be aware of a few potential drawbacks to see if it’s the right fit for your cooking style.

- Not Always Dishwasher Safe: The harsh detergents and high heat in a dishwasher can damage the nonstick coating and sometimes discolor the anodized exterior. It is almost always recommended to hand wash your anodized pots and pans to prolong their life.

- Higher Price Point: The complex manufacturing process makes hard-anodized cookware more expensive than basic aluminum or traditional nonstick pans. However, many find the cost is justified by its long-lasting durability.

- Not Naturally Nonstick: The anodized surface itself is stick-resistant, but it is not truly nonstick like a Teflon-coated pan. This is why most manufacturers add a nonstick coating. If you buy an uncoated anodized pan, you will need to use oil or butter to prevent sticking.

- Nonstick Coating Can Wear Out: If your pan has a nonstick coating, it will eventually wear down over time, just like any other nonstick pan. Using proper utensils (no metal!) and hand washing can help it last much longer.

- Usually Not Induction Compatible: Because the base material is aluminum, most anodized cookware will not work on induction cooktops, which require a magnetic base (like iron or steel). However, some manufacturers now add a bonded stainless steel plate to the bottom to make them induction-ready. Always check the product description if you have an induction stove.

Is Anodized Cookware Safe for Your Family?

This is a very common and important question. Stories about the dangers of aluminum have made some people nervous about using aluminum cookware. However, hard-anodized cookware is widely considered to be extremely safe.

The key is the anodizing process itself. As we learned, this process creates a sealed, hardened surface that is non-reactive. This sealed layer prevents the aluminum core from ever coming into contact with your food. Therefore, you don’t have to worry about aluminum leaching into your meals.

According to the U.S. Agency for Toxic Substances and Disease Registry, part of the CDC, the amount of aluminum we get from food and water is generally not harmful. The barrier created by anodization further reduces any potential exposure from cookware to negligible levels. The surface is stable and won’t break down or corrode, even when cooking acidic foods.

Furthermore, most modern hard-anodized cookware with a nonstick coating is PFOA-free, addressing another common health concern associated with older nonstick pans. When you buy from a reputable brand, you can feel confident that you are using a safe and reliable product.

Anodized Cookware vs Other Popular Materials

How does hard-anodized cookware stack up against other kitchen favorites? Let’s compare it to stainless steel and cast iron to help you decide what’s best for your needs.

| Cookware Material | Pros | Cons | Best For |

|---|---|---|---|

| Hard-Anodized Aluminum | Excellent heat conductor, durable, scratch-resistant, lighter weight, non-reactive, easy to clean. | Often not dishwasher/induction safe, nonstick coating can wear out, can be pricey. | Everyday cooking, from eggs and pancakes to sauces and sautéing. A great all-around choice. |

| Stainless Steel | Very durable, dishwasher safe, oven safe to high temps, won’t chip or peel, great for searing meat. | Poor heat conduction (needs a copper or aluminum core), food can stick easily, can discolor. | Browning meats, pan sauces, and boiling. A favorite of professional chefs for its durability. |

| Cast Iron | Incredibly durable (can last a lifetime), retains heat exceptionally well, naturally nonstick when seasoned. | Very heavy, heats up slowly, requires regular seasoning, can rust if not cared for properly, reactive with acidic foods. | Searing steaks, frying chicken, baking cornbread, and dishes that go from stovetop to oven. |

How to Care for Your Anodized Cookware

To get the most out of your anodized pots and pans and ensure they last for many years, a little bit of proper care goes a long way. Follow these simple tips:

1. Season Before First Use

Even if your pan has a nonstick coating, it’s a good idea to lightly season it before you use it for the first time. Simply wash and dry the pan, then rub a teaspoon of cooking oil over the entire interior surface. Heat it on low for a couple of minutes, let it cool completely, and wipe out any excess oil. This helps condition the surface.

2. Always Hand Wash

This is the most important rule. Even if the manufacturer says it’s “dishwasher safe,” hand washing is much gentler. Use a soft sponge or cloth with warm, soapy water. Avoid abrasive scrubbers like steel wool, which can damage the nonstick coating and the anodized finish.

3. Use the Right Utensils

To protect the nonstick cooking surface, avoid using metal utensils, which can cause scratches. Stick to silicone, wood, or nylon tools. Scratches in the nonstick layer can reduce its effectiveness and lifespan.

4. Avoid High Heat

Anodized cookware is an excellent heat conductor, so you rarely need to use the highest heat setting on your stove. Cooking on low to medium heat is usually sufficient and will help protect the nonstick coating from damage. Never heat an empty pan, as this can cause the coating to break down quickly.

5. Let it Cool Before Washing

Never plunge a hot pan into cold water. This extreme temperature change, known as thermal shock, can cause the pan to warp and may damage the nonstick surface. Let the pan cool down for a few minutes before you wash it.

Frequently Asked Questions (FAQ)

1. Is hard-anodized cookware the same as nonstick?

Not exactly. Hard-anodized refers to the super-strong body of the pan itself. Most hard-anodized pans then have a separate nonstick coating applied to the cooking surface for easy food release. The anodized part provides durability, while the coating provides the nonstick function.

2. Can I use metal utensils on my anodized pan?

It’s best to avoid them. While the anodized aluminum itself is very scratch-resistant, metal utensils will scratch and damage the nonstick coating that is on the inside of most of these pans. Always use wood, silicone, or nylon tools to be safe.

3. Why isn’t my anodized pan working on my induction stove?

Induction cooktops require cookware to have a magnetic base to work. Since anodized cookware is made from aluminum, which is not magnetic, it won’t work on its own. Look for anodized cookware that specifically states it is “induction compatible”—this means it has a stainless steel plate bonded to the bottom.

4. Is it safe if my anodized cookware gets scratched?

Yes, it is still safe. If the nonstick coating gets a scratch, it may lose some of its nonstick properties in that spot. If a deep scratch were to expose the anodized aluminum underneath, it is still safe because the anodized layer is sealed and non-reactive. You don’t have to worry about aluminum leaching into your food.

5. How long does hard-anodized cookware last?

With proper care, a high-quality hard-anodized pan can last for many years. The durable body of the pan can last a lifetime. The lifespan is often determined by the nonstick coating, which may last anywhere from 3 to 7 years, depending on use and care.

6. Can you put anodized cookware in the oven?

Most hard-anodized cookware is oven-safe, but the temperature limit can vary by brand. It usually depends on the handle material. Pans with stainless steel handles can often go up to 500°F (260°C), while those with silicone-gripped handles may have a lower limit, like 400°F (204°C). Always check the manufacturer’s instructions.

The Final Word on Anodized Cookware

So, what does anodized mean in cookware? It means you’re getting a piece of kitchen equipment that is engineered for performance and longevity. It’s the secret behind pans that heat evenly, stand up to daily use without scratching or denting, and provide a safe, stable surface for cooking your favorite meals.

By transforming standard aluminum into a hardened, non-reactive workhorse, the anodizing process gives you the best of all worlds: the superior heat conductivity of aluminum combined with strength that surpasses even stainless steel. Whether you’re a beginner cook looking for a reliable first set of pans or an experienced chef wanting to upgrade, hard-anodized cookware is an excellent and dependable choice.

The next time you’re shopping and see that “hard-anodized” label, you’ll know it’s not just marketing jargon. It’s a sign of quality, durability, and thoughtful engineering, designed to make your time in the kitchen easier and more enjoyable.