Pin fasteners, also known as cotter pins or split pins, are simple yet incredibly effective metal fasteners used to secure components by passing through holes and bending open. They are essential for preventing rotation or loosening in various applications, from securing wheels to keeping parts aligned in machinery and even in everyday household items. Understanding how they work and when to use them is key to ensuring safety and durability in your projects.

Ever felt a little lost when faced with a small metal piece that looks like a bent paperclip, wondering what its purpose is in your DIY project or household repair? You’re not alone! Many of us have encountered these handy little gadgets, known as pin fasteners, and wondered exactly how they work their magic. They might seem simple, but pin fasteners are surprisingly robust solutions for keeping things securely in place, preventing unwanted movement and ensuring the integrity of your assembled items. Don’t worry, we’re here to demystify these essential components so you can use them with confidence.

This guide will walk you through everything you need to know about pin fasteners, from their basic anatomy to their various applications and how to use them effectively. We’ll break it down into easy-to-understand steps, ensuring that by the end, you’ll feel empowered to tackle any project requiring these reliable fasteners. Get ready to discover the unassuming power of pin fasteners!

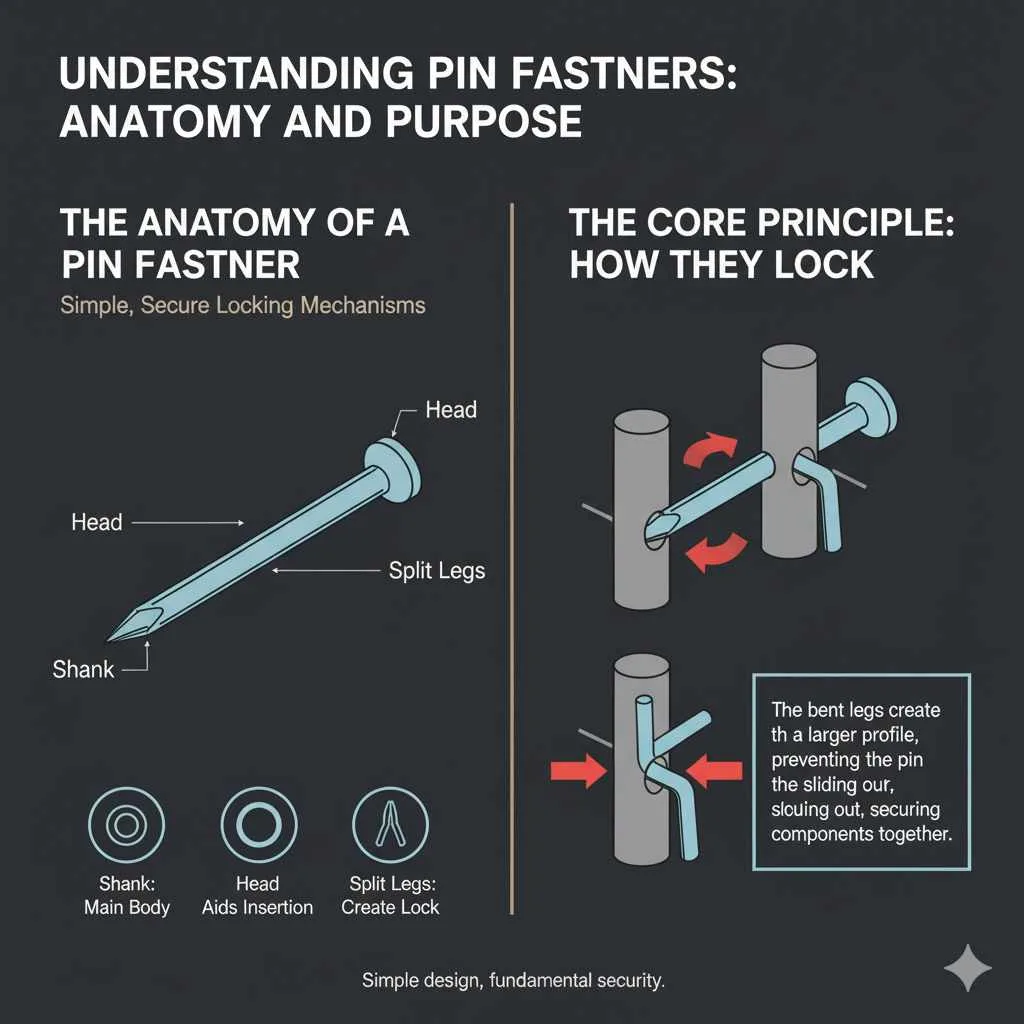

Understanding Pin Fasteners: Anatomy and Purpose

At their core, pin fasteners are designed to provide a simple, secure locking mechanism. They are most commonly recognized as split pins or cotter pins. Let’s explore their basic structure and the fundamental principle behind their function.

The Anatomy of a Pin Fastener

A typical pin fastener has a few key parts:

- Shank: This is the main body of the pin, usually cylindrical or slightly flattened.

- Head: The head is at one end of the shank and helps in insertion and provides a surface to hold onto. It can be flat, round, or specially shaped depending on the application.

- Split Legs (or Ends): This is the defining feature. The opposite end of the shank is split into two legs, which are typically spread apart to allow insertion through a hole.

The Core Principle: How They Lock

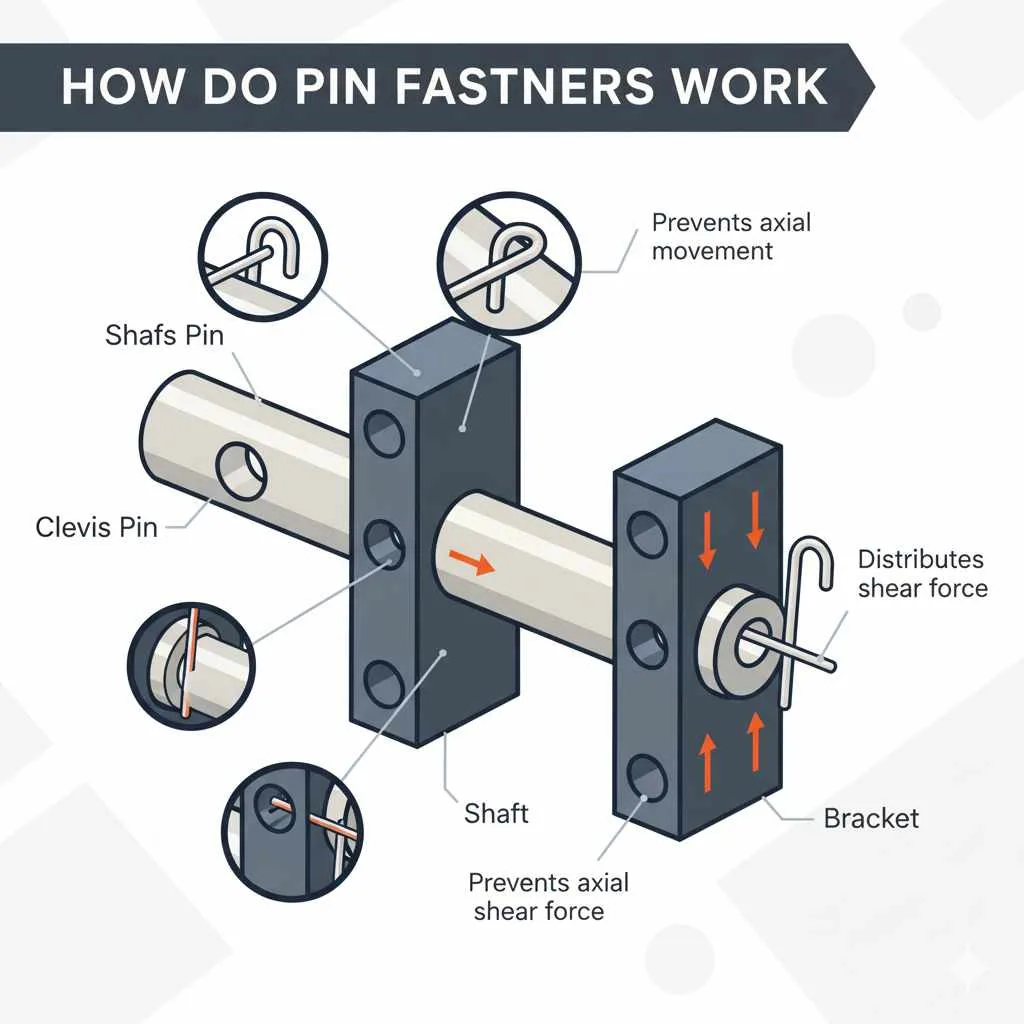

The brilliance of a pin fastener lies in its simplicity and the way the split legs exert outward pressure. When you insert a pin fastener through a hole in a bolt or shaft, and then bend its legs, it creates a secure lock. The bent legs prevent the pin from sliding back out, and in many cases, they also prevent the bolt or shaft from rotating or coming loose.

Think of it like this: The pin goes through a hole. Once through, its split legs are forced apart (or bent apart) to create a larger profile than the hole itself. This larger profile physically stops the pin from being pulled back through the hole. This mechanism is effective in keeping components together and preventing them from disassembling unintentionally.

Types of Pin Fasteners and Their Applications

While the basic concept remains the same, pin fasteners come in various forms, each suited for specific tasks. Understanding these variations can help you choose the right fastener for your needs.

Common Types of Pin Fasteners

- Cotter Pins (Machinery Pins): These are the most common type, featuring two straight legs that are bent outwards after insertion. They are used extensively in automotive and machinery applications to secure castle nuts on bolts, securing components that experience vibration or movement.

- Quick Release Pins: These are more advanced, often featuring a spring-loaded ball mechanism that allows for rapid insertion and removal without tools. They are common in applications where frequent disassembly or adjustment is needed, such as in furniture, exercise equipment, or temporary structures. You can find examples of their use in adjustable shelving units or quick-release bicycle components.

- R-Clips (R-Pins): Shaped like the letter ‘R’, these are simple fasteners with a loop at one end and a single leg that springs into place. They offer a very quick way to secure items and are often found in agricultural equipment, tooling, and temporary fixtures.

- Linch Pins: These are similar to R-clips but generally heavier duty, with a spring that snaps the pin and its head securely into place. They are commonly used on trailer hitches, agricultural machinery, and industrial equipment where a strong, quick locking mechanism is required.

Where You’ll Find Pin Fasteners in Action

Pin fasteners are incredibly versatile and can be found in a surprising array of everyday items and complex machinery:

- Automotive: Securing castle nuts on steering and suspension components, holding brake parts in place, and in various linkages.

- Aviation: Used extensively in aircraft control systems and structural components where reliability is paramount. The aerospace industry relies on high-quality fasteners for safety. You can learn more about general aviation standards at the Federal Aviation Administration (FAA) website.

- Gardening and Agriculture: On lawnmowers, tractors, and other farm equipment to secure PTO shafts, hitches, and other moving parts.

- Home and Furniture: In some chairs, tables, and bunk beds for structural integrity or to allow for easy disassembly.

- Recreational Vehicles: On trailers, ATVs, and bicycles for securing wheels, handlebars, and other adjustable components.

- General Machinery and Industrial Equipment: Wherever a secure, non-permanent fastening is needed to prevent components from dislodging.

How To Use Pin Fasteners: A Step-by-Step Guide

Using a standard cotter pin (the most common type) is straightforward. Follow these steps to ensure a secure fastening for your project.

Tools You Might Need

For most standard cotter pin installations, you won’t need many specialized tools. Here’s what’s typically helpful:

- Your Pin Fastener: Of course! Ensure it’s the correct size and material for the job.

- Pliers: Needle-nose pliers are excellent for gripping and bending the legs of the cotter pin.

- Wire Cutters or Diagonal Cutters: If the cotter pin legs are too long after bending, these can be used to trim them for a neater finish.

- Hammer (occasionally): Sometimes, a gentle tap can help seat the pin properly.

Step-by-Step Installation of a Cotter Pin

Let’s assume you are securing a bolt with a castle nut.

- Prepare the Components: Ensure the bolt, nut, and the hole in the bolt designated for the cotter pin are clean and free of debris. If you’re using a castle nut, thread it onto the bolt until it’s snug, but not overly tight. Line up a slot in the nut with the hole in the bolt.

- Select the Correct Pin Fastener: Choose a cotter pin that is slightly larger than the hole in the bolt. It should fit snugly but not require excessive force to insert.

- Insert the Pin: Place the split (unbent) end of the cotter pin through the hole in the bolt, ensuring it passes through the aligned slot of the castle nut. The head of the cotter pin should rest against the nut.

- Bend the Legs: Once the pin is through, use your pliers to grasp each leg of the cotter pin. Bend one leg outwards, away from the nut, at approximately a 90-degree angle. Repeat with the other leg, bending it outwards in the opposite direction or as needed to create a secure lock. The goal is to prevent the pin from sliding back through the hole.

- Check for Security: Gently tug on the pin to ensure it is firmly in place and the legs are well-bent. The bent legs should prevent the pin from being pulled back through. The pin should also stop the castle nut from rotating.

- Trim Excess (Optional): If the bent legs are excessively long and could interfere with other components, you can use wire cutters to trim them. Be sure to leave enough length to maintain the secure bend.

Tips for Success

- Material Matters: Cotter pins come in various materials like steel (galvanized, stainless), brass, and even specialized alloys. Choose a material that suits the environment and load. Stainless steel is excellent for corrosive environments.

- Size is Crucial: Using a pin that is too small might not provide adequate holding power. Too large, and it won’t fit or could damage the components.

- Never Reuse a Battered Pin: Once a cotter pin has been bent and removed, its integrity is compromised. Always use a new one for reassembly.

- Understand the Purpose: Some applications require the pin to prevent rotation (locking nuts), while others simply prevent parts from sliding apart. Ensure your bending technique achieves the desired outcome.

Pin Fasteners vs. Other Fasteners: When to Choose Which

Pin fasteners are just one type of many available. Understanding their strengths and weaknesses compared to other common fasteners helps in making the best choice for your project.

Advantages of Pin Fasteners

Pin fasteners offer a unique set of benefits that make them indispensable in many situations:

- Simplicity: They are incredibly easy to install and remove with minimal tools.

- Cost-Effective: Pin fasteners are generally very inexpensive, making them an economical choice.

- Vibration Resistance: When properly installed, the bent legs can help resist loosening caused by vibration.

- Visual Indicator: A bent cotter pin is a clear visual indicator that the component is secured.

- Adjustability and Disassembly: They allow for quick disassembly and reassembly, which is crucial for maintenance or for products that need to be stored or transported easily.

Disadvantages of Pin Fasteners

While great, pin fasteners aren’t always the best choice:

- Limited Load Capacity: They are not designed for heavy-duty structural loads compared to bolts and nuts.

- Can Fall Out if Not Bent Correctly: If the legs aren’t bent sufficiently, they can work themselves loose.

- Not Aesthetically Pleasing: The bent legs can sometimes look untidy depending on the application.

- Corrosion: Standard steel cotter pins can rust if not protected or used in humid environments.

Comparison with Other Fasteners

Here’s a quick look at how pin fasteners stack up against other common types:

| Fastener Type | Primary Use | Pros | Cons |

|---|---|---|---|

| Cotter Pin | Securing nuts, preventing rotation, retaining parts. | Simple, inexpensive, easy to use, good for vibration. | Limited load, can be visually unappealing, can fail if bent improperly. |

| Bolt and Nut | Joining two or more components under significant load. | High strength, reliable, precise tightening possible. | Requires tools, can be time-consuming, may require locking mechanisms (like cotter pins) to prevent loosening. |

| Rivet | Permanent joining of materials. | Strong, permanent connection. | Permanent (cannot be easily disassembled), requires specialized tools. |

| Screw | Joining materials, often with a pre-drilled hole. | Good holding power, variety of types for different materials. | Can strip if over-tightened, requires appropriate pilot hole. |

| Snap Ring (Circlip) | Grooved shaft or bore for retaining components. | Compact, holds components securely in axial direction. | Requires a groove, can be tricky to install/remove. |

For applications requiring high structural integrity or precise torque, bolts and nuts are usually preferred. However, for simple retaining or locking functions, especially where vibration is a concern or where easy disassembly is needed, the humble pin fastener shines. For instance, in securing a wheel on a trailer hitch, a linch pin offers a fast and secure solution where a bolt and nut would be cumbersome and time-consuming to manage for frequent detachment.

Safety and Maintenance with Pin Fasteners

While pin fasteners are simple, their proper use is crucial for safety, especially in applications involving moving parts or weight-bearing components.

Ensuring Safety

The primary safety concern with pin fasteners is their potential to fail if not installed correctly. This can lead to components becoming loose or separating, causing catastrophic failure in machinery, vehicles, or structures.

- Always ensure the pin is fully seated and the split legs are bent adequately to prevent it from working loose.

- Use the correct size and type of pin fastener for the application. A pin rated for light duty should not be used in a heavy-duty application. Refer to manufacturer specifications for critical components. For guidance on fastener standards, resources like the International Organization for Standardization (ISO) provide valuable information on fastener specifications globally.

- Regularly inspect pin fasteners on equipment and vehicles, especially if exposed to wear, corrosion, or vibration. Look for signs of bending, cracking, or deformation.

- Never force a pin fastener into a hole. If it doesn’t fit smoothly, there might be dirt, misalignment, or you’re simply using the wrong fastener.

Maintenance and Replacement

Pin fasteners are generally considered consumable items, especially those subjected to stress or frequent movement.

- Inspect for Damage: Before reinstallation or even during operation, check pins for any signs of wear, bending, rust, or stress. A pin that looks stressed or has been subjected to excessive force should be replaced.

- Replace After Significant Stress: If a component that was secured by a pin fastener has experienced a significant jolt, impact, or overload, it’s wise to replace the pin as a precaution.

- Corrosion: If you notice rust or corrosion on a steel pin, especially in critical applications, it’s time for a replacement. Consider using stainless steel pins for wet or corrosive environments to prolong their life and maintain their integrity.

- Keep Spares: For frequently used equipment or vehicles, keeping a small assortment of common pin fastener sizes in a toolbox can save a lot of time and hassle.

Frequently Asked Questions About Pin Fasteners

What is the difference between a cotter pin and a split pin?

There is no difference. “Cotter pin” and “split pin” are interchangeable terms for the same type of fastener, characterized by its split, bendable legs.

Can I reuse a cotter pin?

It is generally not recommended to reuse a cotter pin, especially in critical applications. Once bent, the metal’s integrity can be compromised, and it may not provide the same secure hold. Always use a new cotter pin for reassembly to ensure safety and reliability.

What is the strongest type of pin fastener?

While not technically a “pin fastener” in the same way as a cotter pin, linch pins and quick-release pins often offer higher strength and more robust locking mechanisms due to their design and materials. However, for sheer load-bearing over time, a properly installed bolt and nut system is far stronger.

How do I know what size cotter pin to use?

The cotter pin should be sized to snugly fit the hole it will pass through. The length of the pin needs to be sufficient to pass through the components and allow enough material on the legs to be bent securely. It’s best to measure the hole diameter and the depth required.

What are R-clips used for?

R-clips, or R-pins, are used for quick and easy fastening and unfastening. They are ideal for applications where parts might need to be regularly attached and detached, such as on agricultural equipment, covers, or temporary fixtures where a very fast locking action is desired.

Can pin fasteners be used for structural support?

No, pin fasteners are generally not intended for primary structural support that bears significant loads. They are primarily used for retaining, locking, and preventing rotation in conjunction with other primary fasteners like bolts and nuts.

Conclusion

There you have it! Pin fasteners, whether you call them cotter pins, split pins, linch pins, or R-clips, are fundamental components that offer simple, reliable solutions for countless fastening needs. We’ve explored their anatomy, common types, how to install them correctly, and when they’re the best choice compared to other fasteners. Remember, a correctly installed pin fastener is a secure fastener, contributing to the safety and longevity of your projects, from the tiniest gadget to the most robust piece of machinery.

Don’t let these small parts overwhelm you. With a little understanding and practice, you can confidently use pin fasteners to secure your home decor projects, car repairs, or any DIY endeavor. They are a testament to how simple designs can provide incredibly effective results. So next time you encounter one, you’ll know exactly how it works and how to apply it. Happy fixing, and happy decorating!</

Leave a Reply