Brass burners are generally preferred for their superior durability, resistance to heat distortion, and better long-term performance, though aluminum burners are lighter and often cheaper initially. Choosing the right one depends on your priorities for longevity, heat intensity, and budget.

Are you staring at your stovetop, wondering why those little metal rings look different? Maybe you’re buying a new grill, or maybe your old burner just failed, and now you’re faced with a choice: brass or aluminum? It seems like a small detail, but the material of your gas burner makes a big difference in how evenly your food cooks and how long your appliance lasts. Don’t sweat the technical talk; we’ll break down these two common burner metals into plain English. By the end of this guide, you will know exactly which material is best suited for your needs. Let’s get you cooking with confidence!

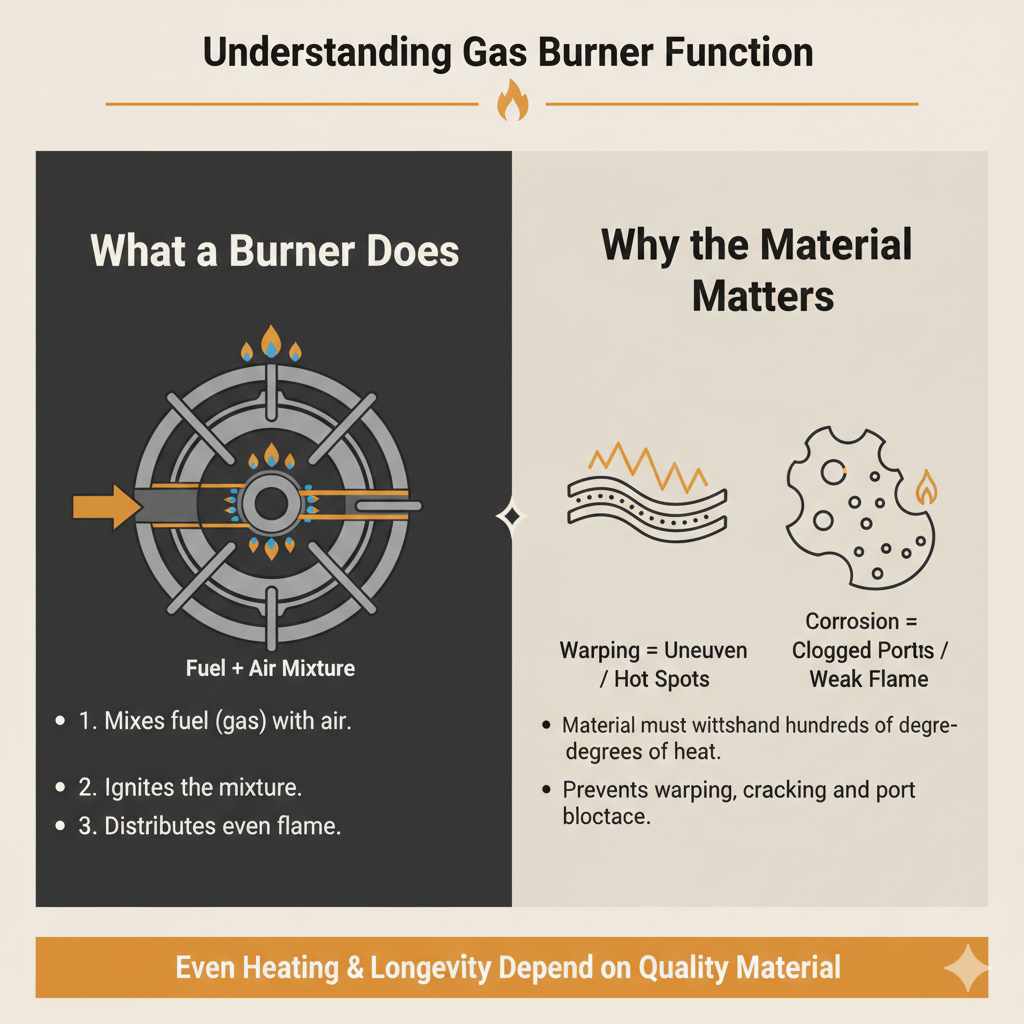

Understanding Gas Burner Function

Before diving into the materials, let’s quickly review what a burner actually does. A gas burner mixes fuel (like propane or natural gas) with air, ignites the mixture, and distributes the flame evenly across the cooking surface. The burner head (where the flame comes out) needs to withstand hundreds of degrees of heat without warping, cracking, or blocking the tiny gas ports.

If the burner warps, the flame pattern becomes uneven, leading to hot spots on your pan or grill grates. If corrosion sets in, the gas ports clog, resulting in weak or uneven flames. This is why the material matters so much.

Deep Dive: Brass Burners

Brass is an alloy, primarily made from copper and zinc. This combination gives it fantastic properties that many long-term appliance owners value highly. Think of brass as the heavy-duty, high-performance option in the burner world.

Pros of Brass Burners

- Exceptional Heat Resistance: Brass has a much higher melting point than aluminum. It resists warping and deformation even under very high, sustained heat, which is crucial for searing or high-volume cooking.

- Superior Durability: It is incredibly tough and resists wear and tear from cleaning, scraping, and constant thermal cycling (heating up and cooling down).

- Corrosion Resistance: Brass stands up well to moisture, grease buildup, and many common oven/grill cleaning chemicals. It rarely rusts or degrades internally.

- Consistent Performance: Because brass doesn’t easily warp, the gas ports stay the correct size over time, ensuring a consistent, reliable flame year after year.

Cons of Brass Burners

- Higher Initial Cost: Brass components are generally more expensive to manufacture than aluminum ones, meaning appliances featuring all-brass burners might cost more upfront.

- Heavier Weight: Brass is denser than aluminum, making the components—and the appliance—slightly heavier.

- Potential for Tarnishing: Over many years, brass can darken or develop a patina (a dulling effect) from exposure to heat and oxygen, although this is mostly cosmetic and doesn’t affect performance.

Deep Dive: Aluminum Burners

Aluminum is a very popular material in modern appliances, especially those seeking to reduce weight and keep manufacturing costs down. It’s an excellent conductor of heat, which sounds good, but we need to look closer at how it performs under the stress of a gas flame.

Pros of Aluminum Burners

- Lower Cost: Aluminum is cheaper to mine and process, often leading to a lower retail price for the finished appliance.

- Lightweight: This is great for portable stoves or maintenance, as parts are easier to handle and ship.

- Good Heat Conduction: Aluminum transfers heat very quickly, which can lead to fast preheating times.

Cons of Aluminum Burners

- Lower Heat Tolerance (Warping Risk): This is the biggest drawback. Aluminum has a significantly lower melting and softening point than brass. If an aluminum burner overheats (due to blocked ports or gas/air mixture imbalance), it can distort or warp. Warped ports ruin your flame pattern.

- Brittleness and Cracking: Over time, repeated rapid heating and cooling cycles can cause aluminum to become brittle, leading to small cracks near the gas ports. Cracks result in leaks or uneven flames.

- Susceptible to Corrosion: While aluminum doesn’t rust like iron, it can suffer from oxidation and chemical pitting from harsh cleaners or spilled, acidic liquids, which can clog the ports.

Brass vs Aluminum Burners: Head-to-Head Comparison

To make the decision easier, let’s put them side-by-side based on the factors a home user cares about most. Think of this as checking the specs sheet before buying a new vehicle.

| Feature | Brass Burners | Aluminum Burners |

|---|---|---|

| Durability / Longevity | Excellent; resists wear and tear | Fair to Good; prone to eventual wear |

| Heat Resistance (Warping) | Very High | Moderate (Can warp under extreme heat) |

| Cost | Higher initial investment | Lower initial investment |

| Weight | Heavier | Lighter |

| Corrosion Resistance | Excellent | Good, but susceptible to long-term pitting |

When Should You Choose Brass Burners?

If you view your stove or grill as a long-term investment and you plan on using it heavily, brass is usually the winner. It’s the choice for chefs and grill masters who need reliability under intense, repeated stress.

Choose brass if you:

- Cook at very high temperatures frequently (e.g., high-heat searing on a gas range or BBQ).

- Want the absolute longest lifespan out of your appliance parts.

- Are replacing a failed burner part on a high-end or older, dependable appliance.

For example, many high-end residential ranges use solid brass components because professional cooks demand consistency. According to guidelines from the National Institute of Standards and Technology (NIST) on material performance under thermal stress, alloys designed for high thermal stability, like those containing significant copper content (like brass), outperform lighter alloys when cycled frequently near their operational limits—which is exactly what stovetop burners do.

When Are Aluminum Burners Acceptable?

Aluminum burners are not inherently “bad”; they are just optimized for different priorities. They are often found in entry-level or portable equipment where cost and weight savings are prioritized over decades of extreme service.

Choose aluminum if you:

- Are looking for the most budget-friendly option available.

- Own a portable camping stove where every ounce matters.

- Use your appliance infrequently or at moderate temperatures.

It’s important to note that even in aluminum burners, manufacturers often use specific coatings or treat the aluminum to improve its heat resilience. However, these treatments can sometimes wear off over time, leading back to the primary concern: warping.

Maintenance: Keeping Your Burners Working Well (Regardless of Material)

No matter which metal you have, proper maintenance keeps your appliance running safely and efficiently. Dirty burners mean poor performance, whether brass or aluminum.

Simple Cleaning Steps for Longevity

- Safety First: Always ensure the gas supply is turned OFF (for grills) or the appliance is completely cool and disconnected from power (for ranges).

- Remove the Caps: Lift off the burner caps and the burner heads themselves. Pay close attention to how they sit so you can reinstall them correctly.

- Clean the Ports: Gas ports are the tiny holes where the flame escapes. Use a small, stiff brush (like an old toothbrush or a dedicated brass wire brush if gentle cleaning is needed) or a thin wire to gently clear any debris or blockage from these holes. Never use a toothpick, as wood pieces can break off and cause a worse clog.

- Wipe Down: Use a damp cloth lightly dipped in soapy water to clean the exterior of the burner heads. For stubborn grease, you can use a degreaser, but rinse thoroughly immediately afterward.

- Dry Completely: This is critical! Ensure the burners are bone dry before putting them back in place. Moisture can interfere with ignition and promote premature corrosion.

For stubborn buildup, especially on aluminum burners where harsh chemicals are a risk, many manufacturers suggest a simple soak in warm white vinegar for 30 minutes, followed by thorough rinsing. This helps break down mineral deposits without being overly aggressive chemically.

Identifying Your Current Burner Material

If you’ve inherited an appliance or are working on a used part, how can you tell if you have brass or aluminum without specialized tools?

Visual and Physical Checks

- Color: Brass usually has a distinct yellowish-gold hue, often looking slightly richer or darker than raw aluminum. Aluminum typically presents as a lighter, duller silver-gray. However, heavy grease or oxidation on either can mask the true color.

- Weight Test: If you can safely remove the burner head and cap, lifting it will give you a rough idea. Brass feels noticeably heavier and more substantial for its size compared to aluminum.

- Magnet Test (Limited): While both are typically non-ferrous (not magnetic), sometimes aluminum parts have steel mounting bolts or internal fittings. This test isn’t definitive but can sometimes rule out common cast iron components often confused with aluminum.

- Age and Quality Clues: Older, high-end American and European appliances are far more likely to use solid brass. Newer, budget models or portable units almost always use aluminum to save on manufacturing cost.

The Impact of Material on Flame Quality

The material directly affects the uniformity of the flame. A good flame should be steady, blue, and shaped like a neat ring or series of teardrops around the entire burner head.

When an aluminum burner warps, the gas ports spread apart unevenly. This results in:

- Yellow tips on the flame (indicating incomplete combustion).

- Uneven heat distribution (hot spots and cold spots).

- Reduced efficiency, wasting gas.

Brass, due to its inherent stability, maintains its port alignment much better. This means consistent, efficient blue flames throughout the burner’s lifespan, provided the gas orifices underneath remain clear.

It’s worth noting that the National Fire Protection Association emphasizes the need for properly functioning combustion equipment to prevent the build-up of carbon monoxide. A warped or clogged burner—regardless of material—is a safety hazard that must be addressed immediately.

Repair vs. Replacement: When to Swap Burners

Figuring out when to replace a burner is a common question, especially when costs start adding up.

When to Consider Replacing an Aluminum Burner:

- Visible Warping: If the metal is visibly bowed or no longer sits flat, it needs replacement.

- Cracks: Any hairline crack near a gas port signals potential leaks or further failure and should be replaced immediately.

- Persistent Clogging: If a burner head simply refuses to stay clean, the ports may have pitted internally due to corrosion, making replacement the only reliable fix.

When to Consider Replacing a Brass Burner:

Brass burners often last the lifetime of the appliance, sometimes decades. Replacement is usually only necessary if:

- The burner has been subjected to an extreme, unusual event (like a major spill of highly corrosive cleaner that was left to sit).

- You are upgrading components or completely overhauling an old range.

If you are replacing a part, always try to match the material of the original component if the appliance was known for good performance. If you have a cheap unit that always burns unevenly, swapping an aluminum burner for a high-quality brass replacement can sometimes improve performance, provided the replacement fits perfectly onto your manifold.

Frequently Asked Questions (FAQ)

Q1: Can I mix brass and aluminum burners on the same stove?

A: Generally, yes, you can mix them if the appliance is designed to use different materials for different sections (like having a simmer burner made of brass and a high-power burner made of aluminum, which sometimes happens). However, you must ensure the replacement part is specifically sized and ported for your stove model to ensure correct gas flow.

Q2: Is a brass burner going to make my food cook faster?

A: The burner material itself does not significantly change the total heat produced, but brass maintains a more consistent flame pattern. This results in more even cooking, which can feel faster because you aren’t wasting time adjusting pans over hot and cold spots.

Q3: How do I clean burnt-on grease from my brass burner?

A: Brass is tough. Use a non-abrasive scrub pad and a heavy-duty degreaser, or make a paste of baking soda and water. For deep buildup, soaking in straight white vinegar for a few hours often loosens the residue effectively without damaging the brass.

Q4: Are aluminum burners safe if they are a little dirty?

A: A dirty burner is never ideal, but aluminum burners are safest when clean. If the ports are clogged on an aluminum burner, the gases build up and often burn around the sides or only emerge from a few spots. This uneven burn leads to warping faster, so cleanliness is extra important for aluminum durability.

Q5: Do I need special tools to replace a gas burner?

A: For simple removal and replacement of the burner head and cap, you usually only need your hands or perhaps a flathead screwdriver to gently pry up stuck components. If you are replacing the main manifold tube or making gas line connections, you absolutely need professional tools and expertise to ensure there are no dangerous gas leaks.

Q6: Why are some new grills advertising “cast aluminum” burners?

A: Cast aluminum is a specific manufacturing process that pours molten aluminum into a mold. This process can create thicker, more robust parts than stamped aluminum. These cast parts tend to be more durable than thin, non-cast aluminum but still do not match the sheer heat stability and longevity of true brass alloys.

Conclusion: Making the Smart Choice for Your Kitchen

Deciding between brass burners vs aluminum burners boils down to balancing upfront cost against long-term reliability. If you are assembling a portable cooking kit or upgrading a secondary outdoor grill you only use a few times a year, the cost savings of aluminum might be perfectly fine for your needs.

However, when it comes to your main kitchen range or a high-use BBQ grill, the initial investment in durable brass components pays dividends. Brass resists the thermal stress that destroys aluminum over time, ensuring you get reliable, even heat for many more cooking sessions without worrying about warped metal or frustratingly uneven flames. By prioritizing durability now, you save time, hassle, and potential repair costs later. Happy cooking, and remember: a little care during cleaning goes a long way for whatever metal you choose!